Enterprise dynamics

Release time:2021.09.11

Publisher:Qingdao Metal Design International Trading Co.,ltd

Qingdao metal design International Trade Co., Ltd. has always believed that the scheduling of stamping workshop is a big problem, because the complexity and diversity of batch conversion, batch sequencing and multi line production make the dynamic scheduling of stamping workshop very difficult, and it is necessary to coordinate all processes, which is conducive to improving the efficiency of processing and production. Therefore, when planning the scheduling of stamping workshop, Qingdao metal design believes that the following points should be fully considered.

1. Stamping parts of product batch shall be considered

Each stamping operation is basically calculated in seconds, but the time required to replace stamping tools is about 10 minutes or even a few minutes. Therefore, stamping plants often process thousands of stamping parts of the same type at a time in order to save costs. However, in the actual scheduling, we should consider not only large quantities of products, but also small batches and several types of products.

2. Consider the different processes for producing different stamping parts.

In the actual production process, the number of processes required to produce different stamping products is fundamentally different. Practical arrangements should take this into account.

3. Considering the processing capacity of the machine.

When stamping stamping parts, the press must meet the impulse required for processing stamping parts. For each punching production line, there shall be at least one press meeting the impulse requirements.

4. Considering the tool change time

The difference between the processing time and tool change time of each punching operation is a very large order of magnitude. The tool change time is not considered when preparing the production plan, which will have a great impact on the actual situation.

5. Considering the transportation time

When a stamping part is processed in one process and then transferred to another press for the next process, the stamping part has a transportation transfer time, which is determined by the distance between adjacent presses. The transportation transfer time in the production process can not be ignored, because a process of a stamping part is usually within a few seconds, and the transportation time is much longer than the stamping time.

6. Considering the flexible operation of the stamping plant.

When planning the production of the stamping plant, many parts manufacturers simplify it into a workshop without considering the flexible production characteristics of the stamping plant.

Sample

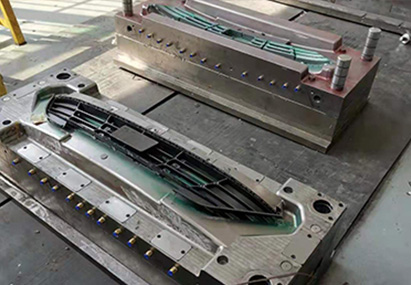

Auto plastic mold & part Service

Auto plastic mold & part Service

Auto plastic mold & part Service

Contact

Company:Qingdao Metal Design International Trading Co.,ltd

Mail:cre@crecompany.com

Address: Shenzhen Road,Qingdao City,Shandong Province,China.

Mob:0086-188 6390 7726

Fax:0086-532-8891 8275

Website:www.dmfgchina.com

Leave us a message.

HOTLINE / 0086

188 6390 7726