Enterprise dynamics

Release time:2021.09.11

Publisher:Qingdao Metal Design International Trading Co.,ltd

As a stamping part of auto parts, I believe many people are not unfamiliar. It exists in many companies and is used for many purposes. It is also widely used.

In the production of automobile stamping parts, a variety of cold stamping processes are adopted to meet the needs of automobile stamping parts industry in variety and large-scale production. For medium and heavy vehicles, most of the decorative parts, such as body outer panels and some load-bearing and supporting parts, such as frame, body and other automobile parts, are automobile stamping parts. The steel used for cold forming is mainly steel plate and strip steel, accounting for 72.6% of the steel used for the whole vehicle. Cold forming materials are closely related to the production of automotive stamping parts. The quality of materials not only determines the performance of products, but also directly affects the process design of automotive stamping parts, and affects the quality, cost, service life and production organization of products.

Metal stamping parts can select raw materials for re inspection, chemical analysis and metallographic inspection according to needs. Analyze the content of chemical elements in the material; Determine the particle size and uniformity of the material; Evaluate the degree of free cementite, banded structure and non-metallic inclusions in the material; Check for material problems such as shrinkage and looseness. Non standard stamping process can be used to process parts with a wide range of sizes and complex shapes, such as stopwatch of watch, side rail and cover plate of automobile, etc. Coupled with the hardening effect of materials in the process of cold forming and stamping, the strength and stiffness of stamping parts are relatively high.

Formability test: conduct bending test and cupping test on the material to determine the strain hardening index n and plastic strain ratio r of the material. The test method of steel sheet formability can be carried out according to the provisions of Steel Sheet Formability and test method. Determination of other performance requirements: Determination of electromagnetic properties of materials and adhesion ability to coatings, etc.

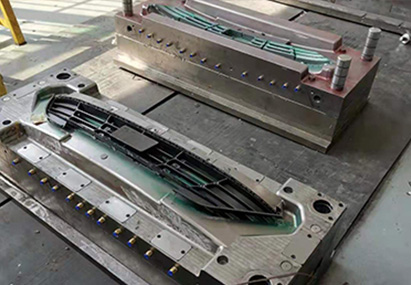

Sample

Auto plastic mold & part Service

Auto plastic mold & part Service

Auto plastic mold & part Service

Contact

Company:Qingdao Metal Design International Trading Co.,ltd

Mail:cre@crecompany.com

Address: Shenzhen Road,Qingdao City,Shandong Province,China.

Mob:0086-188 6390 7726

Fax:0086-532-8891 8275

Website:www.dmfgchina.com

Leave us a message.

HOTLINE / 0086

188 6390 7726