Product Encyclopedia

Encyclopedia

Sample

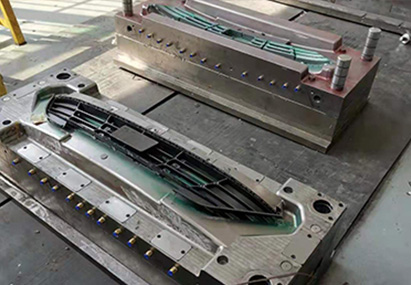

Auto plastic mold & part Service

Auto plastic mold & part Service

Auto plastic mold & part Service

Release time:2021.09.11

Publisher:Qingdao Metal Design International Trading Co.,ltd

For the welding of large structural members, to ensure that each weld can be welded, it is necessary to ensure that there are conditions around the weld for the free operation of welders and the normal operation of welding devices. This condition is called welding accessibility.

In the actual welding process, some welding parts are not easy to contact, that is, their welding accessibility is poor, which brings inconvenience and difficulty to the welding operator. In order to ensure poor accessibility and low welding quality, corresponding welding process measures shall be formulated. The main process measures include:

1. Groove form

For groove processing method, manual groove can be used for simple and small workload, mainly filing, grinding and other methods. Beveling machine is mainly used for regular pipe beveling with large pipe diameter and wall thickness greater than 5mm..

2. Preheating before welding

Preheating can slow down the cooling rate after welding, which is conducive to the escape of diffused hydrogen in the weld metal and avoid hydrogen induced cracks; At the same time, it also reduces the hardening degree of weld and heat affected zone, and improves the crack resistance of welded joints.

3. Post weld stress relief

Stress relief heat treatment is to reduce the yield strength of the welded workpiece at high temperature, so as to relax the welding stress. There are two common methods, one is overall high-temperature tempering, the other is local high-temperature tempering

4. Reduce deformation and residual stress

Slow cooling after welding is to keep the workpiece warm after welding (such as placed in asbestos cloth or raw stone ash) and let the workpiece cool slowly to eliminate internal stress. Slow cooling is more important for high carbon steel, alloy steel and cast iron workpieces.

Contact

Company:Qingdao Metal Design International Trading Co.,ltd

Mail:cre@crecompany.com

Address: Shenzhen Road,Qingdao City,Shandong Province,China.

Mob:0086-188 6390 7726

Fax:0086-532-8891 8275

Website:www.dmfgchina.com

Leave us a message.

HOTLINE / 0086

188 6390 7726