Product Encyclopedia

Encyclopedia

Sample

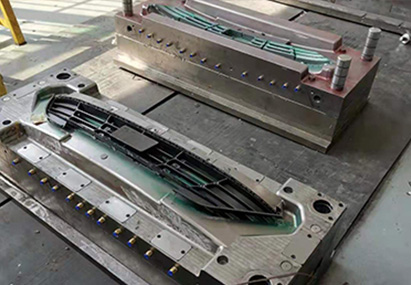

Auto plastic mold & part Service

Auto plastic mold & part Service

Auto plastic mold & part Service

Release time:2021.09.11

Publisher:Qingdao Metal Design International Trading Co.,ltd

In the process of making automobile plastic molds, the structural form and processing quality of molds will directly affect the quality and production efficiency of automobile plastic products.

Some problems will inevitably occur in the production of automobile plastic molds. Next, I'll introduce some solutions to some inter factory faults.

1. Difficult gate stripping: in the process of injection molding, the gate is stuck in the gate sleeve and is not easy to come out. The main reason for this failure is the poor finish of the gate taper hole and the knife mark in the circumferential direction of the inner hole. In addition, the material is too soft, the small end of the conical hole is deformed or damaged after being used for a period of time, and the spherical radian of the nozzle is too small, resulting in the riveting head of the gate material here.

2. Guide post damage: in the following cases, the moving and fixed mold will produce huge lateral offset force during injection: when the wall thickness of plastic parts is required to be uneven, the rate of material flow passing through the thick wall is large, resulting in large pressure here; The side of the plastic part is asymmetric, such as the mold with stepped parting surface, and the back pressure on the opposite two sides is not equal.

3. Dynamic and fixed mold offset: large molds have dynamic and fixed mold offset due to different filling rates in all directions and the influence of mold self weight during mold installation.

4. Moving template bending: when the injection mold is injected, the molten plastic in the mold cavity produces a huge back pressure, generally 600-1000 kg / cm2.

Contact

Company:Qingdao Metal Design International Trading Co.,ltd

Mail:cre@crecompany.com

Address: Shenzhen Road,Qingdao City,Shandong Province,China.

Mob:0086-188 6390 7726

Fax:0086-532-8891 8275

Website:www.dmfgchina.com

Leave us a message.

HOTLINE / 0086

188 6390 7726